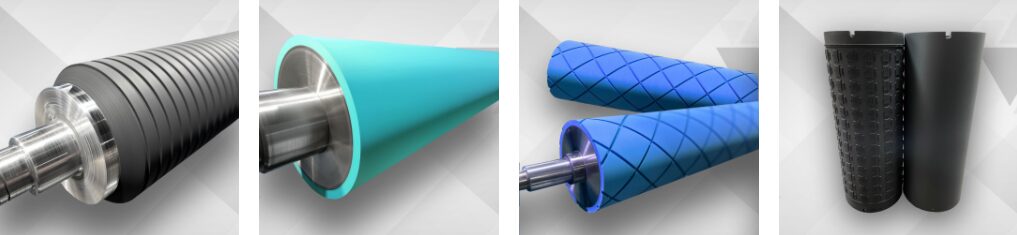

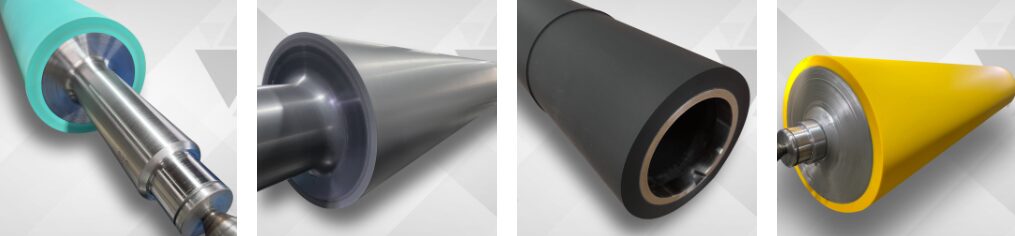

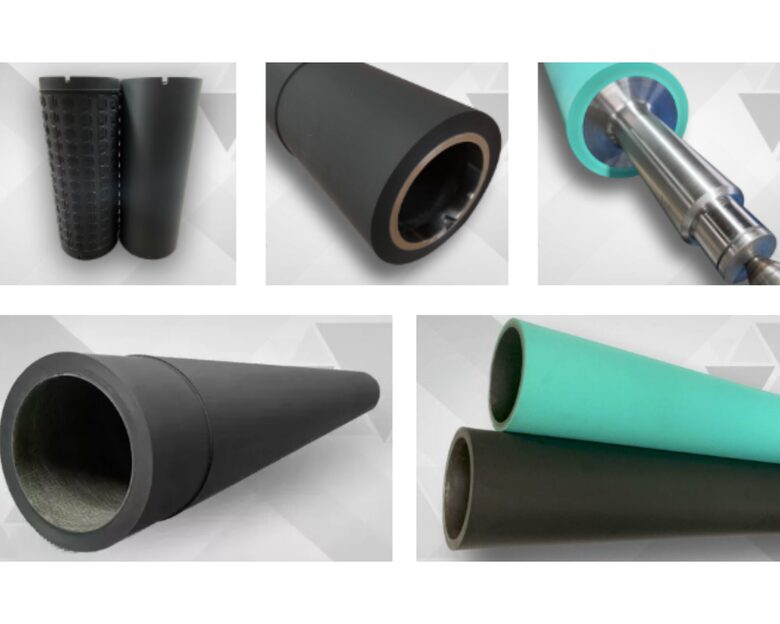

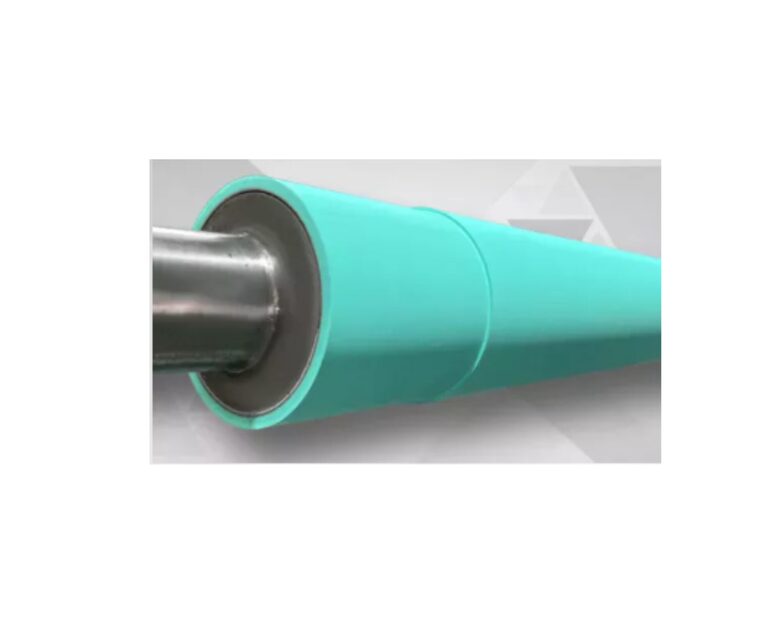

RUBBER SLEEVES

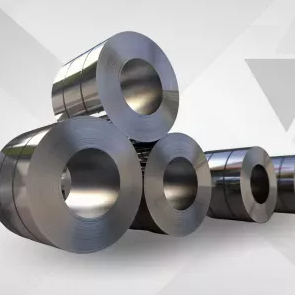

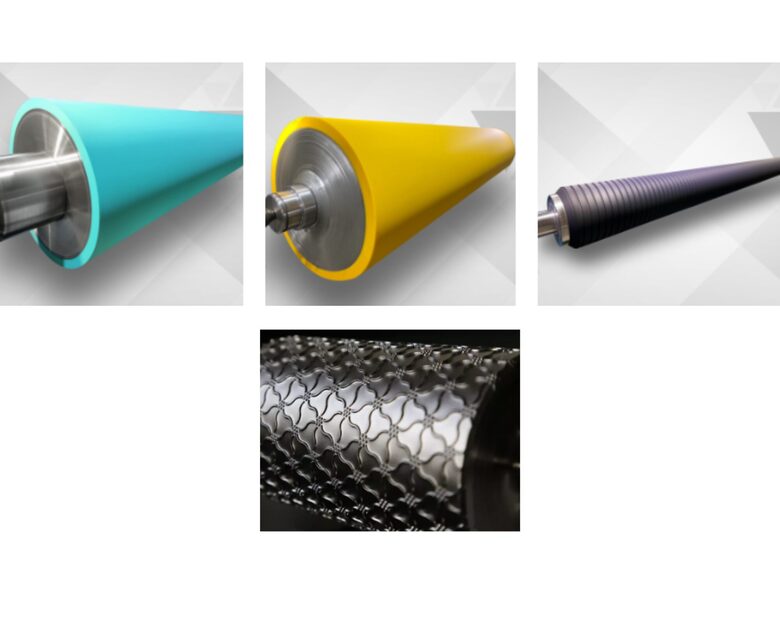

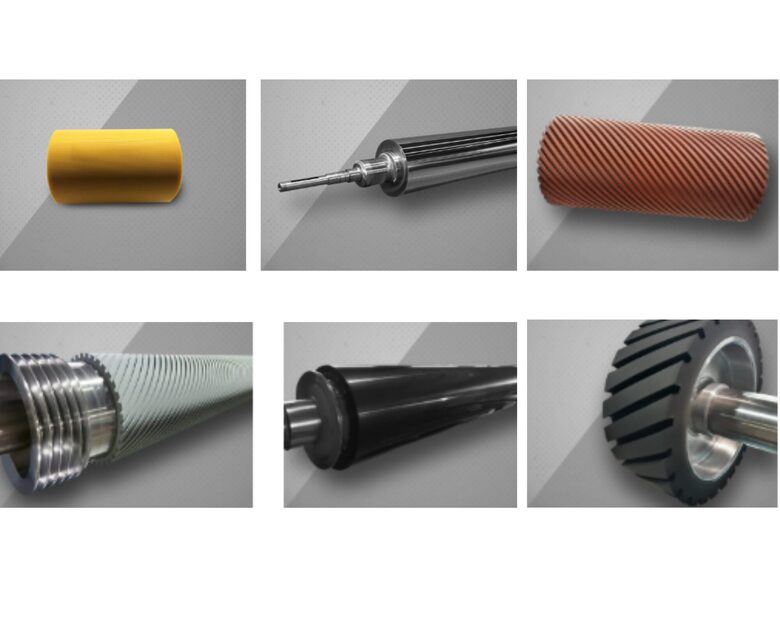

We offer the production of steel rollers and rubberizing rollers in one plant. The comprehensive offer is complemented by refurbishing of chrome rollers, refurbishing of polyurethane rollers and refurbishing of anilox rollers and sleeves.

We refurbish rollers for machines from packaging, printing, paper and wood industries as well as other industries where rubber rollers are used.

In addition to rubberizing, we also offer grinding of rollers with high precision, such as printing rollers, ink rollers, varnishing rollers or glue rollers.